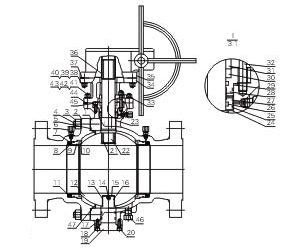

Worm Gear Operation High Pressure Ball Valve Trunnion Mounted Preventing Leakage

- Availability: In Stock

- Product Model: Q347F

Worm Gear Operation Trunnion Mounted Flanged Ball Valve For High Pressure Service

Specifications for Trunnion Ball Valve:

1) Material: A105, F304, LF2

2) Size rating: NPS 6"-30"

3) Working Pressure: CLASS 150~2500 LB

4) Design Standard: ASME B16.34-2004

5) Face To Face Standard: ASME B16.10

9) Flange End: ASME B16.5, ASME B16.47

10) Test Standard: API 598

Materials

Carbon steel (ASTM A216 WCB) and stainless steel (ASTM A351 CF8M) are the materials which form the standard supply. Other materials can be supplied upon request.

Fire-Safe

In the event of fire, a secondary metallic seat prevents leakage through the valve port. A graphoil stem seal and a graphite spiral wound body gasket with PTFE inner layer ensures tightness through the stem packing and body joints.

Gland Packing

Two Belleville spring washers ensure optimal sealing performance, also compensating for changing process conditions. Advantages of this feature are an increased operational safety and less maintenance. In accordance with fire-safe requirements, the packing material is made of Graphoil.

Anti-static

The ball-stem connection and the stem-body connection have an anti- static feature, which ensures electrical continuity between those parts.

Direct Mount

A Direct Mount top-flange according to ISO 5211 is standard for these Ball Valves. This feature makes it possible to mount an actuator without the need of a mounting bracket and drive adapter. This gives a considerable cost reduction, compact automated unit and a higher level of safety for operators.

Ball

The highly polished solid ball has a pressure relief hole in the stem slot in order to avoid pressure build-up in the body cavity. This ensures a tight shutoff and long service life.

Stem

The valve stem assembly has a blow-out proof construction and a square top connection. A PTFE thrust washer seal helps to achieve a low operating torque.

Seats

A flexible seat design provides tight shut-off at high and low pressures. The special seat construction limits wear to a minimum and ensures low torque values under all operating conditions. Standard seat material is a high grade PTFE. Besides the proven mechanical and chemical properties of PTFE, this chemical reinforced version offers suitability for a wider range of applications in respect to pressure and temperature.

Testing

The Ball Valves are 100% tight and are tested in accordance with API 598 (ASME)